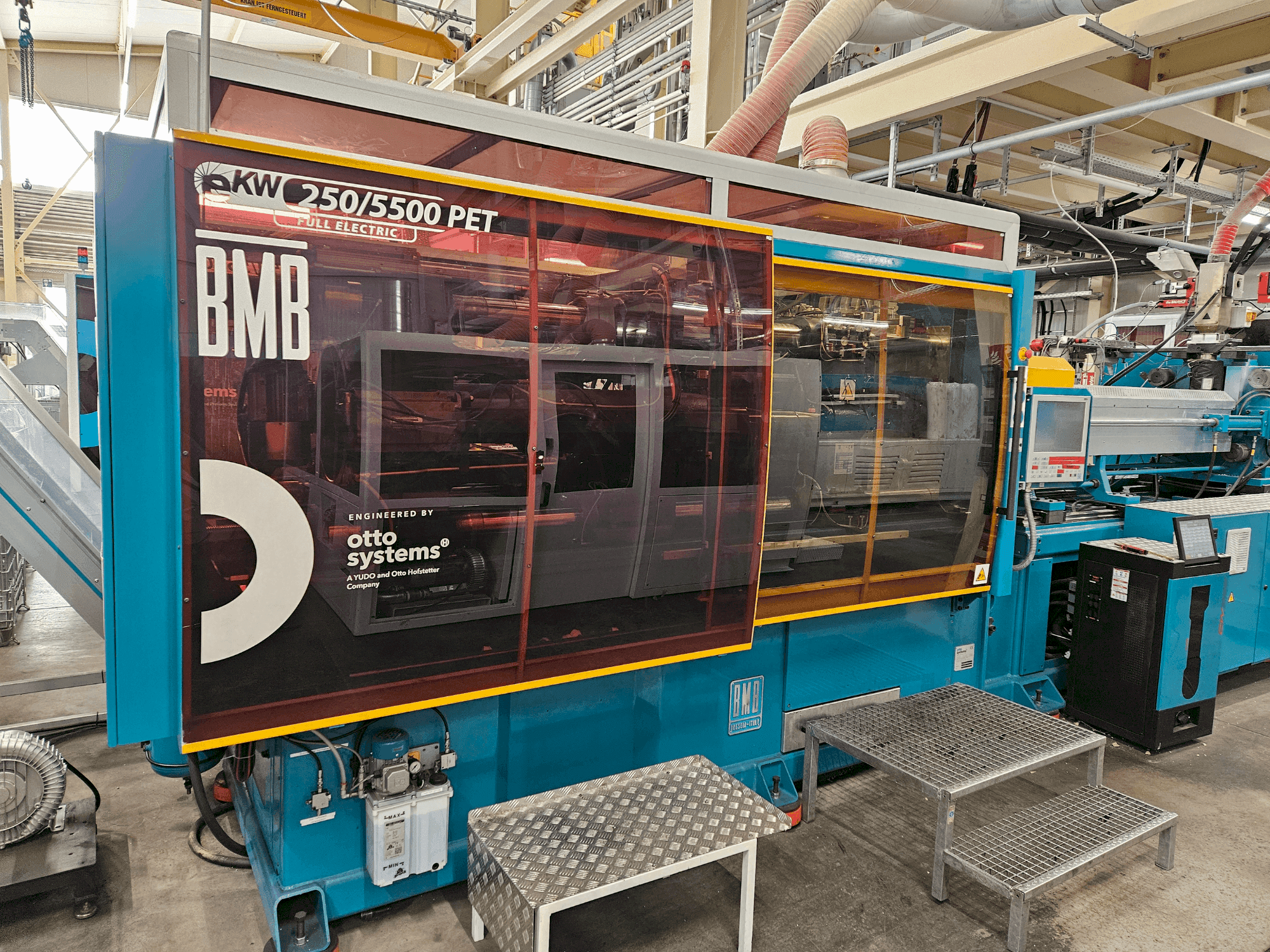

Otto Systems - eKW 250/5500 PETDE-INJ-OTT-2018-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ➤ Used Otto Systems eKW 250/5500 PET | Injection Moulding

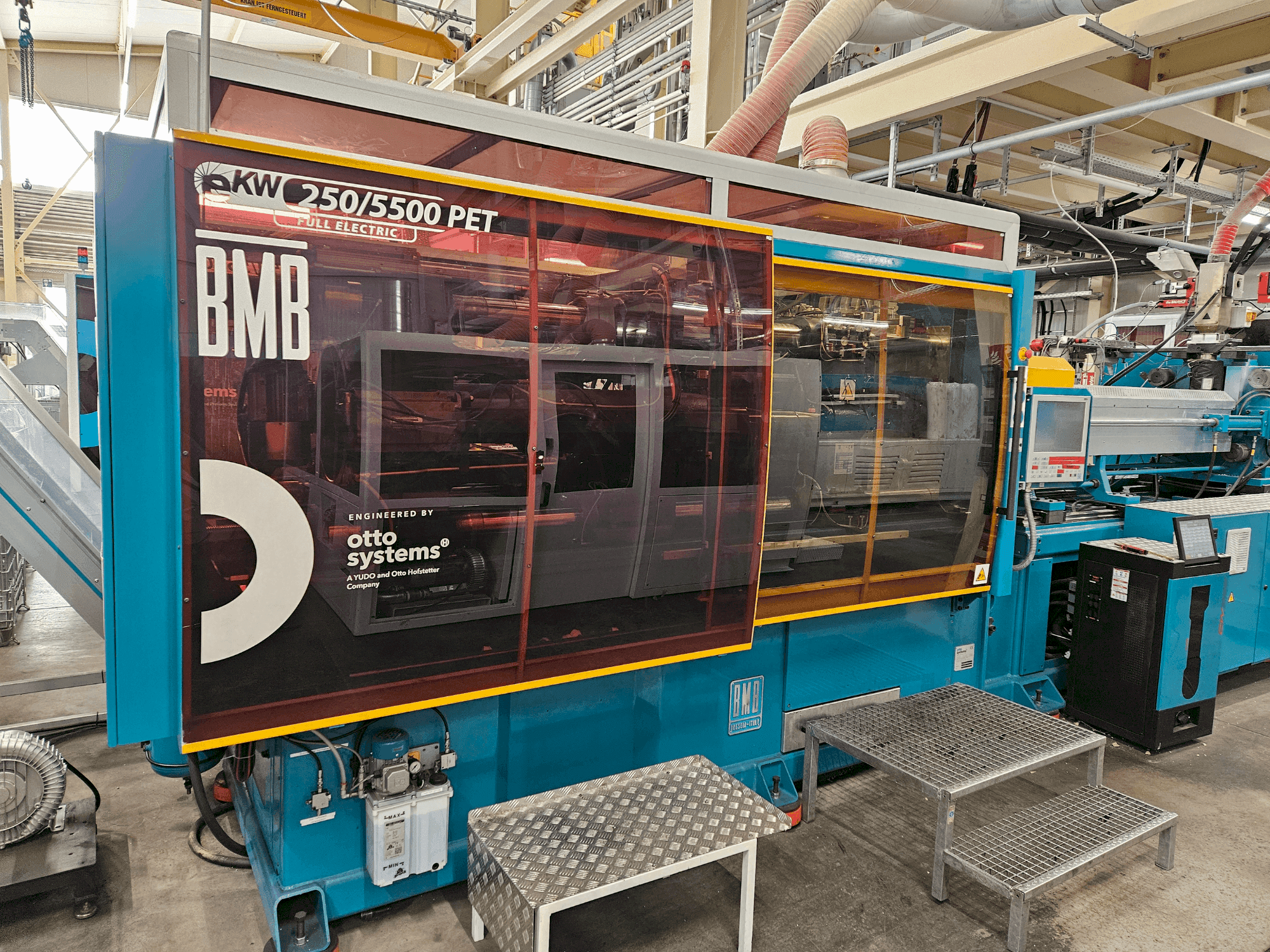

This Otto Systems eKW 250/5500 PET was manufactured in 2018. It features a clamping force of 2500 kN, a screw diameter of 100 mm, and a maximum injection speed of 250 mm/s. The machine has a dry cycle time of 1.6 seconds and a total weight of 22000 kg. If you are looking to get high-quality injection molding capabilities, consider the Otto Systems eKW 250/5500 PET machine we have for sale. Contact us for more information.

Overview

- brand: Otto Systems

- year: 2018

- MODEL: eKW 250/5500 PET

- production hours: 40365

- application type: Injection Moulding

- Location: Germany

- machine type: Electrical Injection Moulding Machine

Technical Information - Otto Systems eKW 250/5500 PET

General Data

- Machine weight: 22000 kg

Injection Unit

- Screw diameter: 100 mm

Clamping unit

- Clamping force: 2500 kN

- Opening stroke: 650 mm

- Max open daylight: 1500 mm

- Distance between bars: 630 x 630 mm

- Ejector stroke: 200 mm

- Ejector force for / back: 60 kN

Additional Information

Additional equipment

- Injection unit: 13000 kg

- Clamping unit: 9000 kg

- only hot runner is includeed

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing

Products related to Otto Systems eKW 250/5500 PET

ALLROUNDER 1200 t 1000 - 400

Arburg - Hydraulic Injection Moulding Machine

ALLROUNDER 370 S 600-290 U

Arburg - Hydraulic Injection Moulding Machine

Concept 420/810-2300

DEMAG - Hydraulic Injection Moulding Machine

320 C 500-100 + Multilift H with B-Axis

Arburg - Hydraulic Injection Moulding Machine

SYNERGY 1500-600

Netstal - Hydraulic Injection Moulding Machine

ES200/40 HLS

Engel - Hydraulic Injection Moulding Machine

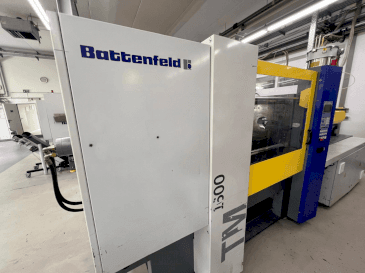

TM 1600/1000

Battenfeld - Hydraulic Injection Moulding Machine

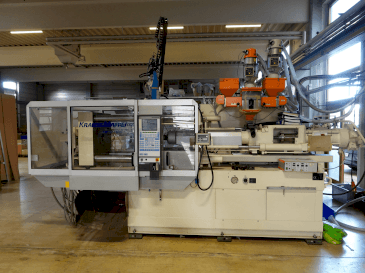

KM 150-1000 C1

Krauss Maffei - Hydraulic Injection Moulding Machine

Allrounder 920H 5000-4600

Arburg - Hydraulic Injection Moulding Machine

55A

BOY - Hydraulic Injection Moulding Machine

duo 2400/650

Engel - Electrical Injection Moulding Machine

Intec 250/1110

INVERA - Hydraulic Injection Moulding Machine