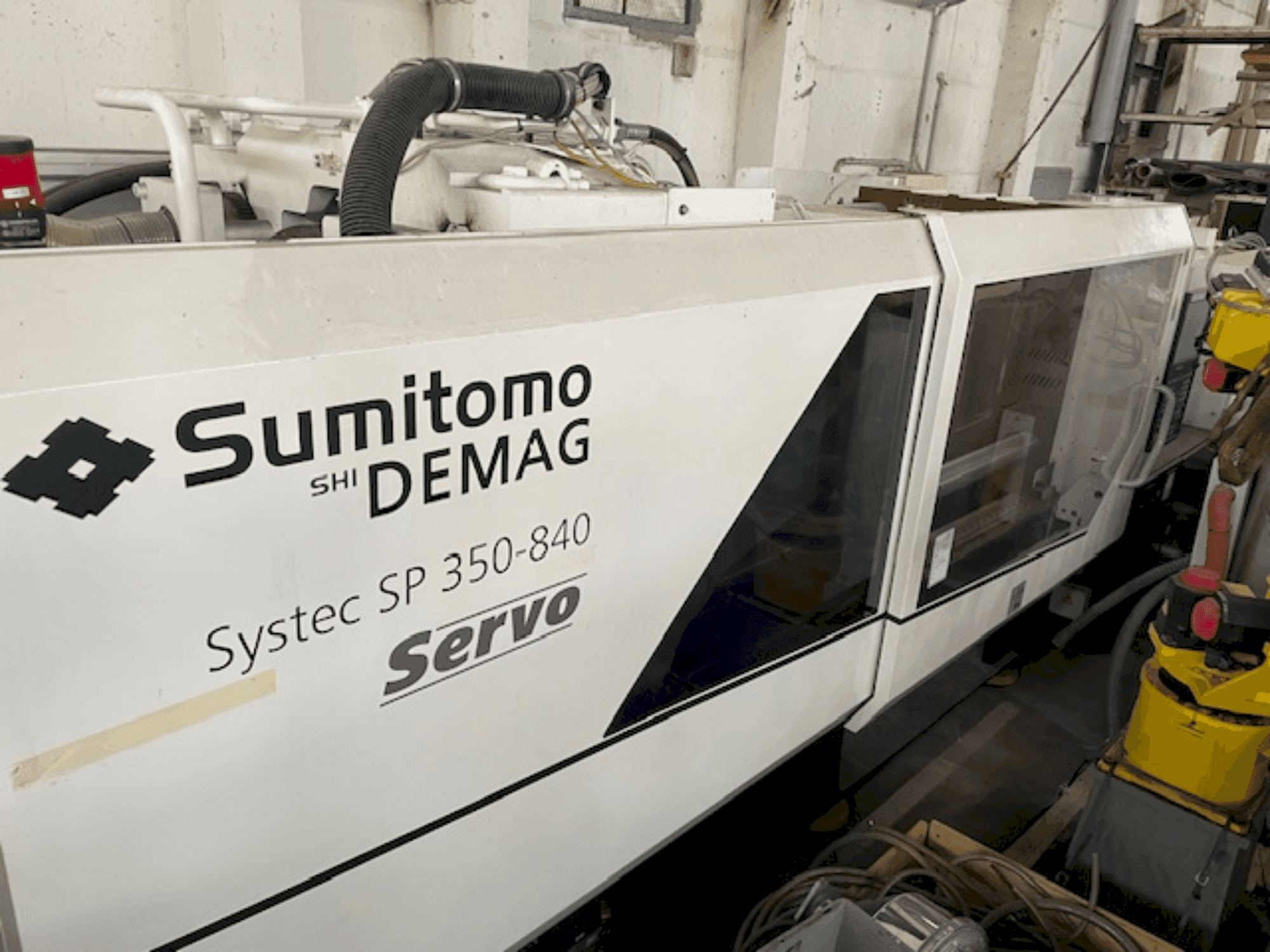

SUMITOMO SHI DEMAG - Systec SP 350/720-840DE-INJ-SUM-2015-00002

Rs. 7,617,422

gindumac price

(Ex works)

get an official quote

Visit the machine

make a counteroffer

Download PDF

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

Click to chat on WhatsApp

- GINDUMAC

- Products

- Plastics Processing Machinery

- ➤ Used SUMITOMO SHI DEMAG Systec SP 350/720-840 For Sale

Show in original language

This SUMITOMO SHI DEMAG Systec SP 350/720-840 was manufactured in 2015. It is a hydraulic injection moulding machine, ideal for precision plastic processing. Consider the opportunity to buy this SUMITOMO SHI DEMAG Systec SP 350/720-840 hydraulic injection moulding machine. Contact us for more information.

Overview

- brand: SUMITOMO SHI DEMAG

- year: 2015

- MODEL: Systec SP 350/720-840

- production hours: 15642

- application type: Injection Moulding

- Location: Germany

- machine type: Hydraulic Injection Moulding Machine

Technical Information - SUMITOMO SHI DEMAG Systec SP 350/720-840

Dimensions

- Machine Depth: 6950 mm

- Machine Height: 2213 mm

- Machine Weight: 15750 kg

Technical Specification

- Screw Diameter: 45 mm

Additional Information

Additional equipment

- Fanuc Robot

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Your account manager:

Sergi Guardia

Sergi Guardia is one of our used machinery trading experts and will be your direct contact for any further questions on the machine. Feel free to contact him/her.

Payment Terms

Payment in advance

Asset Financing