Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

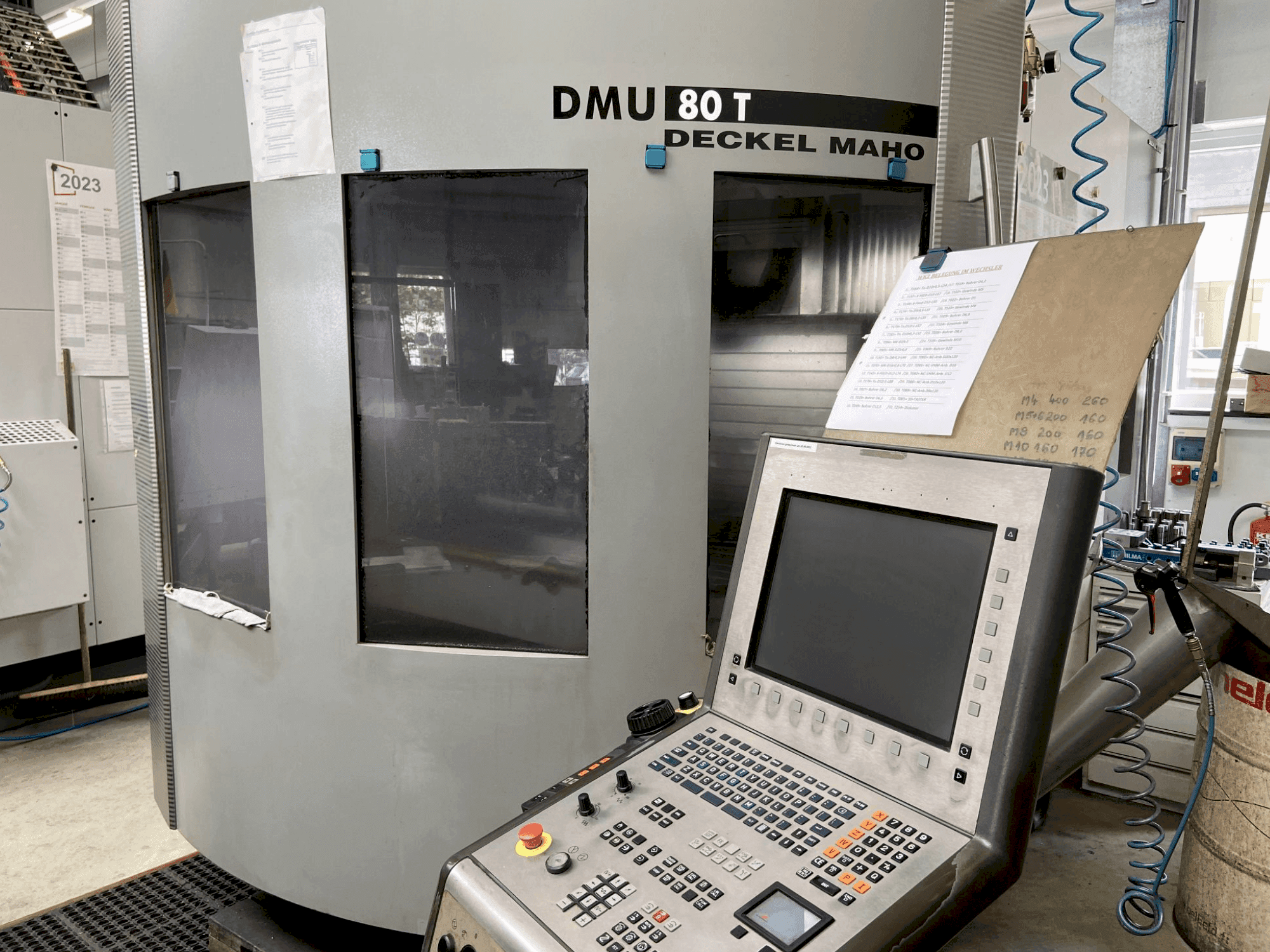

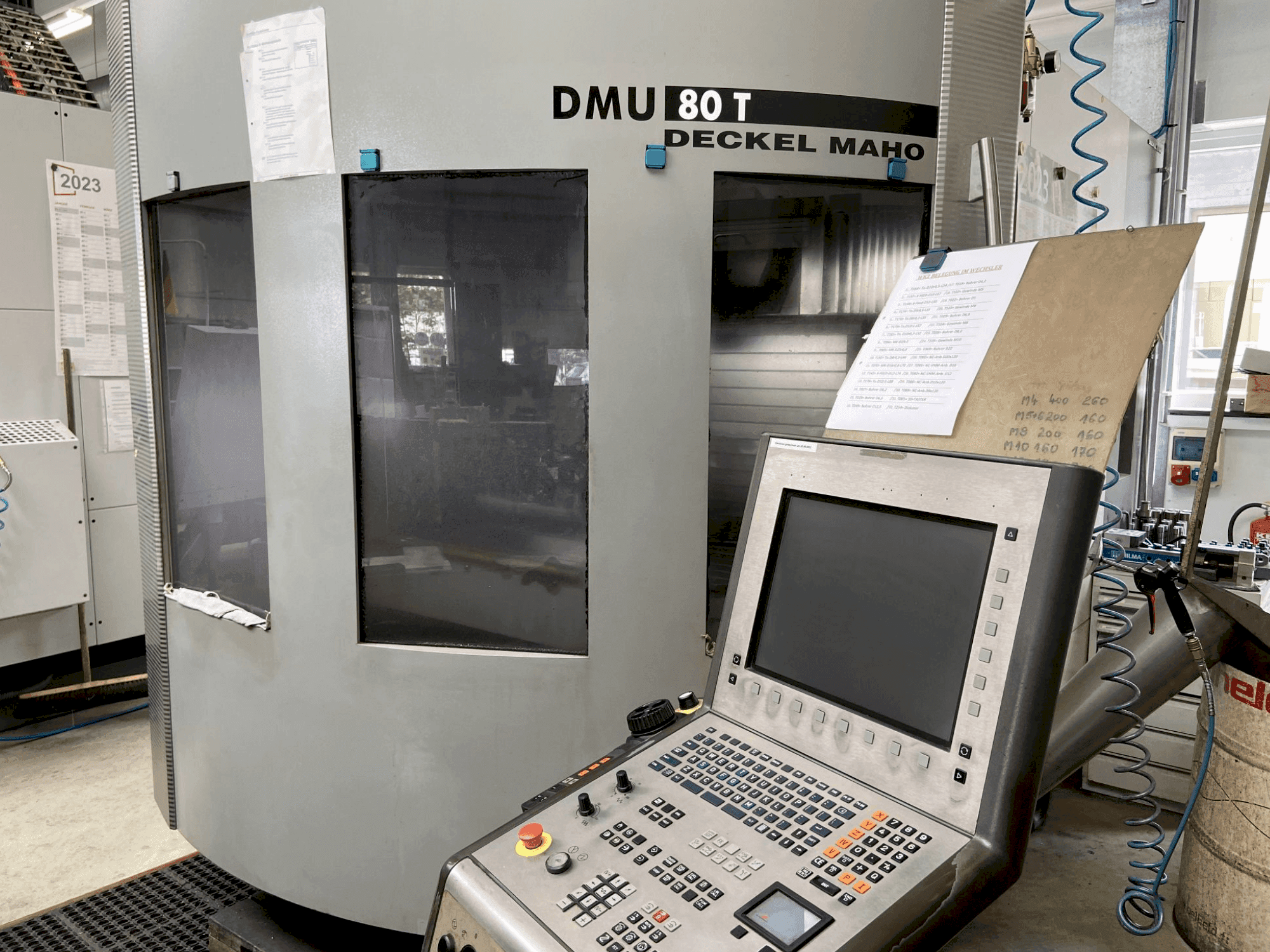

DECKEL MAHO - DMU 80 TDE-MIL-DEC-2002-00005

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- DECKEL MAHO DMU 80 T (2002) Universal Machining Center

This DECKEL MAHO DMU 80 T (2002) Universal Machining Center was manufactured in 2002 in Germany. It is equipped with 3+2 axis (B-axis and NC dividing head), a 12,000 rpm spindle and a 32 tool magazine. The machine runs with tool taper SK 40 and is controlled by a Heidenhain control unit with iTNC 530 model. Electronic handwheel , spiral conveyor and 3D path control are available. It is still in operation, and has always been in single-shift production. The machine works accurately, even if Y-axis has some play, which can result in a slightly wavy surface structure during fine finishing. Fits/stitch dimensions can be achieved in the +/- 0.015 range. The tool changer flap falls when the machine is at a standstill for a longer period of time (cylinder fastening worn out). Overall machine is in good, reliable working condition and can be inspected anytime. The spindle was replaced in September 2017 and has approx. 5700 hours. See photo and video gallery for detailed impressions - or original delivery note (German) attached for all technical positions.

Overview

- brand: DECKEL MAHO

- year: 2002

- MODEL: DMU 80 T

- production hours: 25602

- application type: Milling

- Location: Germany

- machine type: Universal Machining Centre

- control unit brand: HEIDENHAIN

Technical Information - DECKEL MAHO DMU 80 T

Control Unit

- Model: iTNC 530

- Brand: HEIDENHAIN

Main drive

- Number of spindles: 1

- Spindle speed range: 12000 rpm 1/MIN

- Spindle motor power: 10kW (100% ED)

- Tool taper: SK 40

- Number of axis: 5 (3+2)

Movement

- X-AXIS Movement: 880 mm

- Y-AXIS Movement: 630 mm

- Z-AXIS Movement: 630 mm

Tools

- Number of stations: 32

Additional Information

Additional equipment

- Electronic handwheel

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing

Products related to DECKEL MAHO DMU 80 T

GX 600

Bridgeport - Vertical Machining Centre

TC 32B

Brother - Vertical Machining Centre

HS500i

HYUNDAI KIA - Horizontal Machining Centre

F5

Makino - Vertical Machining Centre

MTV 655/60N

Mazak - Vertical Machining Centre

DECKEL MAHO DMC 60H Linear

DMG - Horizontal Machining Centre

NHP 5000

DN SOLUTIONS - Horizontal Machining Centre

UMC-500SS

HAAS - Universal Machining Centre

LASERTEC 65 3D Hybrid

DMG MORI - Universal Machining Centre

TM 2

HAAS - Vertical Machining Centre

Robodrill D21MiA5

FANUC - Vertical Machining Centre

MC 535

STAMA - Vertical Machining Centre